Shape tolerances

Highest level of quality and precision

Deviation limits and dimensional tolerances for hot rolled steel sheet piles made of unalloyed steel according to din en 10 248-2.

- Pile width

Single piles ± 2%; double and triple piles ± 3% - Wall thickness

t: up to 8.5 mm = ± 0.5 mm; over 8.5 mm = ± 6 % t - U-Sections

s: up to 8.5 mm = – 0.5 mm; over 8.5 mm = – 6 % s - Wall thickness, Z-Sections and flat sections

t, s: up to 8.5 mm = ± 0.5 mm; over 8.5 mm = ± 6 % s, t - Height of U-Sections

h: up to 200 mm = ± 4 mm; over 200 mm = ± 5 mm - Height of Z- Sections

h: up to 200 mm = ± 5 mm; from 200 to 300 mm = ± 6 mm; over 300 mm = ± 7 mm - Deviation from straightness

The longitudinal deviation from straightness must not exceed 0.2% of pile length - Pile length

Sheet pile lengths are permitted to deviate by ± 200 mm from the ordered lengths - Cut

Cut at right angle to the longitudinal axis. The total deviation between the highest and lowest points in the cutting plane, measured on a single pile along the longitudinal axis, must not exceed 2% of pile width - Weight

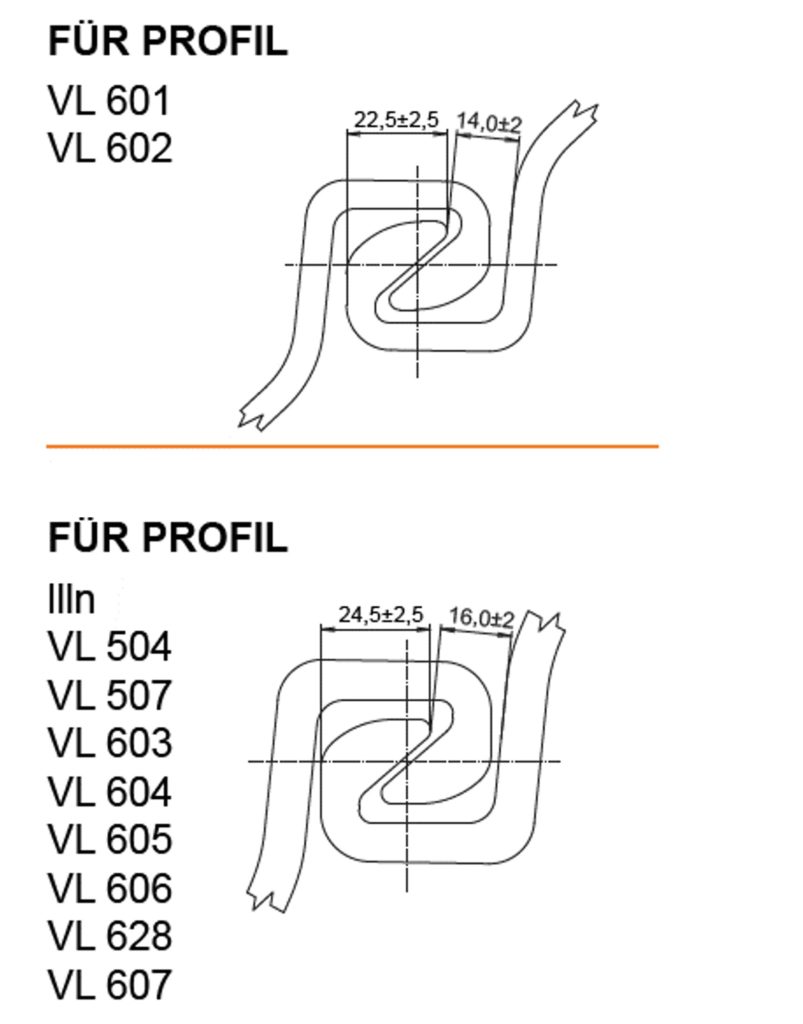

The tolerance between the arithmetic weight (according to section tables) and weighed weight of the total consignment must be within ± 5% - Section interlocks

The interlocks shall have adequate free play so that the piles can be fitted into each other and they must engage in such a manner, that the forces necessary for the calculated connection can be transmitted

Do you want to find out more about the shape tolerances of our steel sheet piles? Get in touch with us today!